Along the way as we turn we pick up wood turning tips that may be too short for an article but too good not to share. I will add to and change these pages as I have time. Hope these help. Be sure to check the contents page for other tips as some are hidden in other pages of the site.

Wood Turning Tips - 1

Wood turning tips are always sought after by turners and most turners love to share their favorites.

Make a bowl depth gauge

In response to some questions raised about using a metal tap in wood, here is a simple tip that is handy to most turners. A bowl gauge is used to identify how far you have gone in a bowl or vase. Cut a piece of wood as long as you plan on turning a bowl diameter plus a couple of inches. I.e. a guage for ten inch maximum bowls will use a twelve inch long piece of wood. Drill a 7/32" hole at center, rotate the wood 90 degrees and drill a 1/4" hole. Use a 1/4" x 20 tap to thread the 7/32" hole. Insert a piece of 1/4" dowel through the unthreaded hole and a 1/4" bolt or thumbscrew through the threaded hole. The dowel is set to desired depth and the wood piece serves as a stop at the bowl's edges. A hint I learned from Jacques Vessery is to replace the dowel with an antenna from a portable radio when doing long vases. It is light and easily retractable for storage. If you can not find an antenna, I find a magnetic pickup from the dollar store to work well.

A simple marking gauge

I like to use a pencil in a marking gauge but this is as easily made by driving a nail through the end of the dowel and sharpening the tip with a file. Cut a piece of wood to desired shape and drill a hole for a 1/2" dowel. Drill a 7/32" hole at right angles into the first hole through the edge of the wood piece. Tap the 7/32" hole 1/4" x 20 for a standard 1/4"bolt. Drill a hole in the end of the dowel large enough for a pencil to fit comfortably and a 7/32" hole at right angles. Tap the 7/32" hole 1/4" x 20 for a set screw or short bolt. Insert the bolts, dowels and pencil.

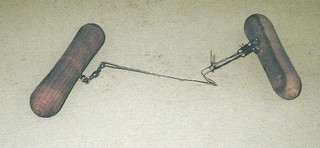

Make a Burning Wire

A simple decorative line can be made on a piece by holding a wire to it while it turns. Holding both ends of the wire in your bare hands can be hot and cutting. A quick solution is to go to the sports store or the sports section of the hardware and buy a few wire leaders from the fishing section. One is sufficient but they are usually carded so make a few for friends. Take or make a couple of dowels and insert screw eyes in the centers. Clip one end of the leader to one eye and open the other eye with pliers. Inert the loop on the leader and close the eye. To try it out first cut a small groove in a spindle. Holding one handle of the wire in each hand, press the wire into the spinning wood until the smoke comes up. Done.

Hint: I find the leaders come with a wire braid that quickly heats off but the core lasts for ages.

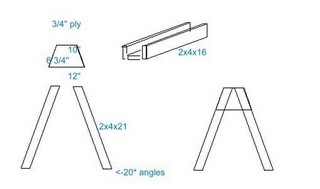

Make a Sawbuck

I find a saw buck has to be simple or it is not used. Here is one for the shop or wood pile, while below is one for the woods. This one can be made from 1 1/2 economy studs. Cut 4 lengths each 21 inches long with a leg angle of 20 degrees, three pieces each 14 to 16" long, and two trapezoids from 3/4" ply about 6 to seven inches deep and 10 inches across the top by 12 inches along the bottom. Nothing is crucial here. I basically laid a 2x4 over a 2x4 unitl the angle looked right and then drew it onto the plywood. The plywood is fastened to the 2x4 with yellow glue and nails. The trough is considered throw away after the saw chews it up over the next year or so. It is three pieces of 2x4 glued and nailed together. The trough holds the whole thing together. I screwed it to the legs with countersunk 2 3/4" long decking screws. The holes drilled on the top serve to hold a couple of peices of 3/8" dowelling to serve as bench dogs as necessary.

Portable Sawbuck for the Woods

The idea for this is simple. You plan on going to the woods or to a neighbor's or some other place where a tree is downed. You want to carry home as much product as possible without carrying home waste. You need a safe way to hold the wood while cutting out blanks. This can be made from 2x4, 4x4 or some combination thereof. I just cut 1/2 a stud into 12" lengths and nail them to the form shown. The channel holds a log for cutting. It is light and easy to carry.

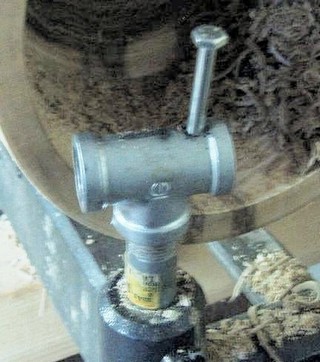

Pivot Point for Deep Hollowing

As I was clearing the inside of a 10" diameter by 7" deep flower pot I found that I was wrestling a bit with a hook to clear the wood. Not surprising when reaching that far over the rest and cutting at 90 degrees to the angle of the shaft. I needed a pivot support to work against so I took a galvanized nipple and tee fitting I had and made one. I drilled a hole in the tee, tapped it for a 1/4x20 bolt, inserted the bolt so it bottomed out in the tee and fitted the nipple into the tee and into the banjo. Works great. These are sometimes known as gates but I have no idea why.