A Course in Woodturning

by Milton and Wohlers; 1919

|

A-I--5-a. Concave Cuts The concave cuts as a rule will give the pupil considerable trouble at first owing to the fact that the grind, which forms the cutting edge and which must be held perpendicular to the cylinder at the start, is on the under side of the tool and cannot be seen. However, as soon as the correct angle of the tool is located, the cut will be found as easy as any. Concaves are usually made with a medium sized gouge either the ½" or ¾". |

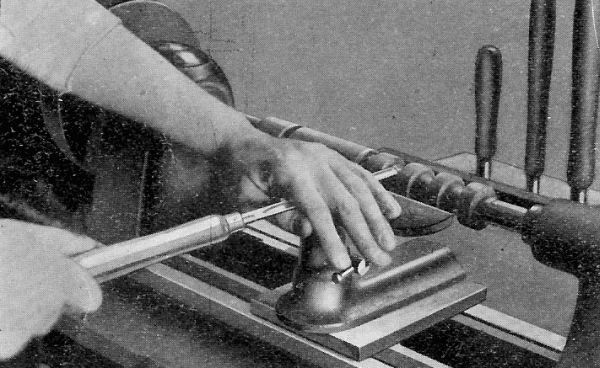

Place the gouge on the rest with the grind or cutting edge well above the wood. The tool is then rolled on its side so that the grind at the cutting point, which is on the lip of the gouge well below the center, is perpendicular to the axis of the cylinder. Fig. 11.

Fig. 11.

Slowly raise the handle to force the gouge into the wood. As soon as the gouge has taken hold, the tool is forced forward and upward by a slight lowering of the handle, while at the same time it is rolled back toward its first position. Care should be taken not to roll the chisel too fast or a perfect arc will not be cut.

By this triple action the grind, which comes in contact with the surface of the curve, forces the lip sidewise and cuts one quarter of a circle. Reverse the position of the gouge and cut from the other side in the same manner to form the other half of the semi-circle. The cutting should always stop at the base of the cut as there is danger that the tool will catch when cutting against the grain of the wood on the other side. Repeat this operation until within about 1/16" of the required size. At the end of each successive cut the tool should have been forced far enough forward and upward to bring the grind or nose of the chisel well out on top of the cut. Fig. 12.

Fig. 12.

The exact depth of the concave is then calipered in the usual manner as described before. A finishing cut is then taken after the cut has been tested with a templet.